Today we, finally uncovered the port side iron ballast. This was slightly shorter than the starboard side at 2.44 meters and 0.73 meters at maximum width. This too finished at around the same point which was the break in the hull. The challenge with these two chunks of iron is that it masks any other iron items in the immediate area. The gradiometer rings six feet away from them and the metal detector also is affected. However, from surveying along the port side exposed frames there clearly is a large iron mass. Whether this is more iron bars under all the ballast stone is yet to be proven.

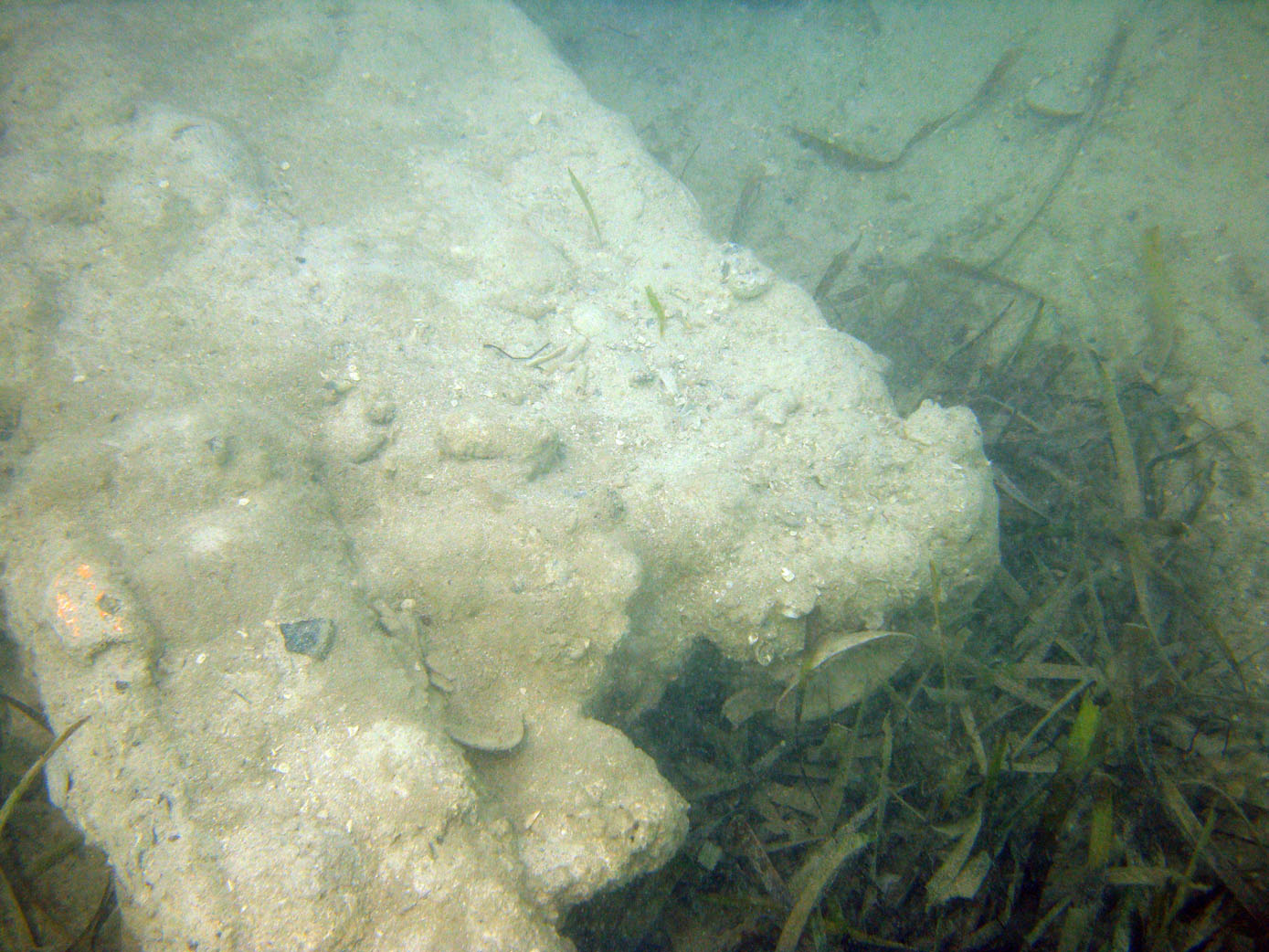

The two pieces of hull planking from Le Dragon with copper sheeting which were found around 50 meters from the break in the hull. It is assumed they were deposited here as a result of the explosion.

The Team also went to finish uncovering the two planks with copper sheeting on them which were 23 meters to the north of the grid. They were left in situ because it was not known how strong the copper sheeting on the underside would be. One of the interesting factors about the copper sheeting was its strength. In the 200 survey the bow section was examined and the copper sheeting looked solid and almost like plate sheeting. However, on the small sections of loose sheeting, we have found this is different. Yes there is the thickness which is the concretion but a few pieces just snapped when moving them or the concretion came off to reveal that the copper sheeting was very thin. In fact, on some parts, it was like looking at a plant leaf seeing all the vanes and the thinness between. We had in effect ghost copper concretions, which was the first time I have ever seen this. On other wrecks like Le Casimir the copper sheeting was not even concreted and remained flexible but not eroded. The Dragon’s was completely different. Thick concretions and then almost sub-millimetre thickness with sections totally gone within the concretion. Further samples need to be recovered and a chemical breakdown of the copper analysed to see what impurities have created this unusual effect.

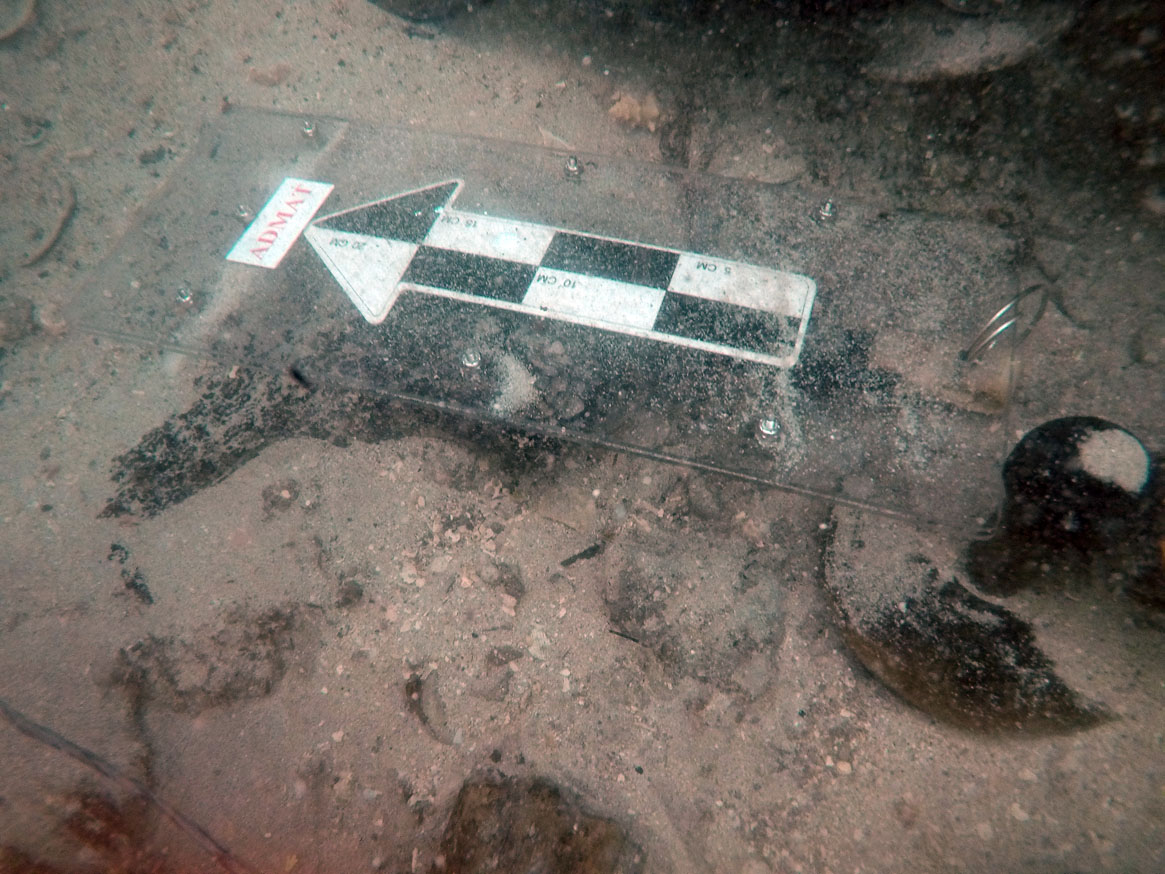

A piece of lead sheeting with a bronze nail, located close to the stern grid.

A piece of concreted copper sheeting which was in effect a “copper ghost concretion”.